Farm Equipment Paint Spray Booth – Case Study | For over 80 years, our client has been manufacturing and delivering versatile solutions for progressive soil management. Their equipment is designed to work in conjunction with many other farm implements to help save farmer’s time and money. It was a pleasure to work with them on this comprehensive project.

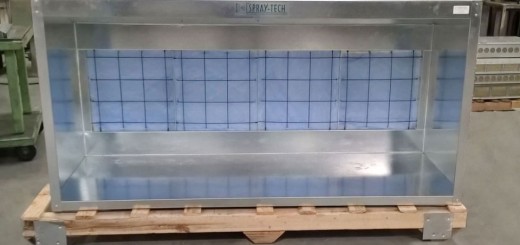

Project Needs –  Our client was constructing a new building in California for their new equipment manufacturing facility. Since everything they manufactured needed to be painted, it was determined that the facility would be requiring a large enclosure for painting operations, which would have to be about 26′ W and 60+’ long. A spray booth of this size moves a great amount of air. To ensure optimum air circulation efficiency, the installation of an air makeup unit was recommended and the client agreed.

Our client was constructing a new building in California for their new equipment manufacturing facility. Since everything they manufactured needed to be painted, it was determined that the facility would be requiring a large enclosure for painting operations, which would have to be about 26′ W and 60+’ long. A spray booth of this size moves a great amount of air. To ensure optimum air circulation efficiency, the installation of an air makeup unit was recommended and the client agreed.

Timeline & Cost – The first meeting of Spray Tech / Junair’s team with the client was held in May of 2013. After regular interactions, an agreement was made in December 2013 and the project was completed by July 2014.

Operations – Initially, the client wanted a downdraft booth (Vertical Airflow). It was eventually determined a cross draft (horizontal airflow) would be more suitable for the industrial finishes they required. By switching from a downdraft to a cross draft booth, where substantially less airflow would be needed, the cost of the project was much closer to clients budget. Later during the project our engineering and sales team advised a booth mounted heater with recirculation, twin variable speed motor drives and Spray Tech / Junair’s “Energy Saver” feature for more energy efficiency in the long run.

Results – Th e break-even for these extra expenses occurred quite quickly. Without these additional features, it would have been a huge problem in the winter as their “Paint/Bake” hours would have been limited. Very conservative calculations show that with the combination of VSD’s, recirculation and idle mode, a minimum of $16K annual savings would be experienced.

e break-even for these extra expenses occurred quite quickly. Without these additional features, it would have been a huge problem in the winter as their “Paint/Bake” hours would have been limited. Very conservative calculations show that with the combination of VSD’s, recirculation and idle mode, a minimum of $16K annual savings would be experienced.